Michelin doesn’t want you to buy as many EV tires

The tire maker Michelin provides original-equipment tires for seven out of 10 EVs sold in the U.S. And yet it acknowledges that EV drivers shouldn’t be buying as many tires as they are.

It’s a technology challenge on multiple fronts. EVs wear through tires quicker, as they weigh more and their torque-rich motor systems tear away more persistently at the tread.

Michelin sees a future in which its tires might be more expensive but last much longer and be much less impactful on the environment. For a company built around a wearable item with a finite service life, that’s an unexpected tack.

“Our goal is not just to sell more tires; we want to sell better tires—in multiple ways,” summed the company’s North American CEO Alexis Garcin at a recent sustainability summit the company hosted in Sonoma, California.

Michelin Uptis airless tire on French postal van

There, executives confirmed to Green Car Reports that the company is pushing ahead on airless tire technology that may be smarter for robotaxis and other autonomous vehicles. It also provided an update on how it’s working to effectively reinvent retread technology with sustainability in mind, allowing the original tire plus four retreads to provide up to a million miles of service in heavy commercial trucks.

“If you start to think in a way that you want to limit your innovation because of the (cost) premium, it could mean we are losing a lot of opportunities,” explained Garcin as to why Michelin keeps investing in long-game technologies.

Michelin moving toward fossil-free materials

In the meantime, Michelin’s short game for this decade includes getting more sustainable and renewable materials into its tires, and making them last longer while saving energy for EVs. Michelin has targeted 40% renewable and recyclable materials across all its tires by 2030, on the way to 100% fossil-free by 2050.

At Sonoma Raceway, it also provided an on-the-road look at part of that future with mass-market tire technology that will likely go into production in 2025.

Michelin 45% sustainable tire. – 2024 prototype

The Primacy A/S demonstration tire offers at least 42% sustainable content—45% in the version shown. That’s more than double what such tires offer today, in a product that Michelin attests, performs as well or better than today’s offerings. It’s made with recycled steel, recycled carbon black from end-of-life tires, with silica from pulverized rice husks, as well as some natural resins and oils—including from orange peel for higher efficiency.

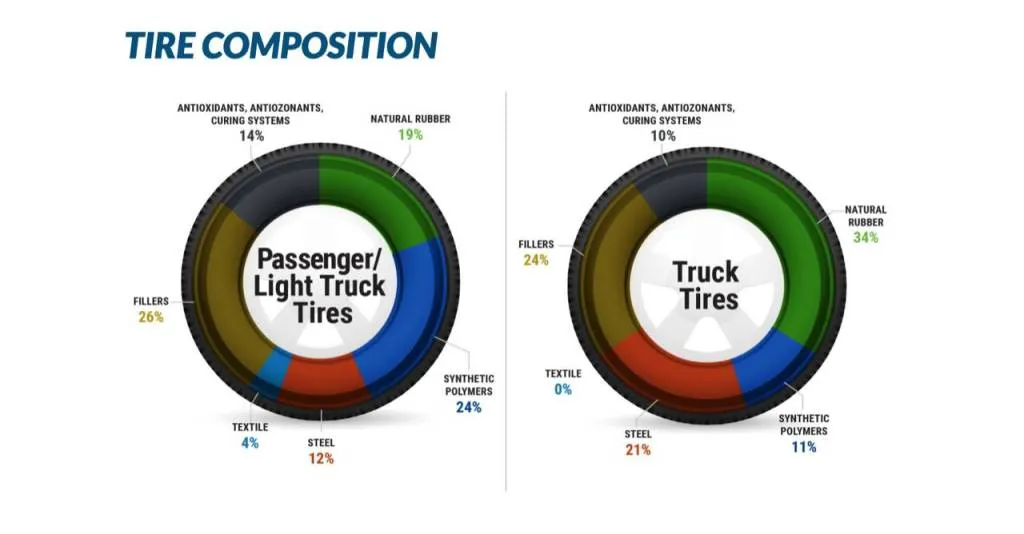

Natural rubber is nearly a fifth of the composition of modern passenger-vehicle tires, and Michelin is making efforts to extract it from sustainable crops like guayule in the American Southwest.

Other tire makers have shown concepts with much higher levels of sustainable content, but what makes the Primacy A/S demo tire different is that it’s production-ready.

Michelin Primacy all-season tires with 42% sustainable content – on Ford Explorer

Michelin Primacy all-season tires with 42% sustainable content – on Ford Explorer

Michelin Primacy all-season tires with 42% sustainable content – on Ford Explorer

Michelin showcased the tire mounted on a new Ford Explorer. On Sonoma Raceway, in noise, grip, and overall performance, it felt like these tires could be interchangeable with the stock Michelin Primacy all-seasons.

The green tire was showcased along with several EVs that include original-equipment Michelin installations, including the Porsche Taycan and Genesis GV60, underscoring that Michelin sees the sustainability factor as especially important in EVs.

Michelin taking custom approach in optimizing for EV range

The performance and durability of tires comes down to three core aspects: the structure of the tire and its core design, the tread, and the compound. With EVs, more rolling resistance can mean more energy lost not only when accelerating and cruising, but also during regenerative braking, so it can have a great effect on the efficiency of EVs overall.

Cyrille Roget, the company’s director of scientific and technical communications, underscored to Green Car Reports, it’s a matter of mapping out the usage needs and then optimizing for the lowest level of rolling resistance. It takes a lot of simulation tools to provide a match for the car, then rounds of final testing with the car.

In the era of EVs with very different weight distribution and power delivery, to go along with their additional weight, that may mean more customized tires.

EVs, hybrids, and PHEVs: Same tire advancements needed

“It does not change so much, the way we consider the market and the way we design tires,” said Garcin, when Green Car Reports asked what’s different about the tire demands for hybrids. “You still have the same effect of this incredibly high torque and the increased weight of the vehicle, so that we just leverage the same technologies to accompany these trends, whether it’s fully electric or hybrid.”

Regarding the compound, there are more than 200 ingredients in typical tires, and carbon black is one of the most important for establishing durability and strength with low rolling resistance.

Michelin has created a consortium called BlackCycle in which it is looking at developing a value chain locally in Europe around secondary raw materials—especially carbon black—to be used in new tires, rather than see the tires shipped across the world.

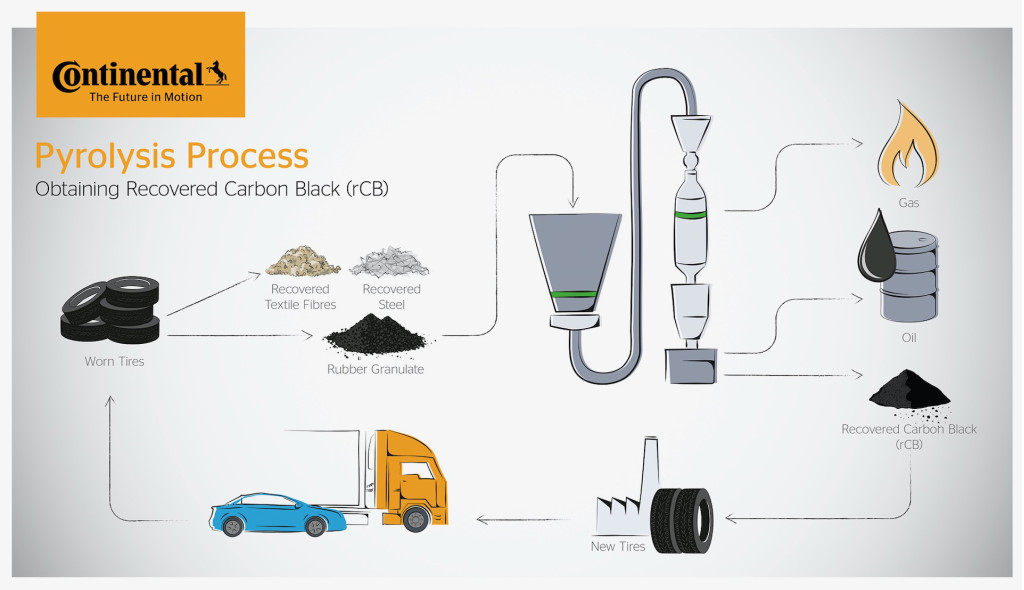

Pyrolysis process used to extract recyclable material from Continental tires

Restarting the loop with carbon black

That led to an evaluation of the global supply chain for carbon black and whether the companies could get more out of pyrolysis, which is the process of heating them without oxygen to recover compounds. It results in recovered carbon black plus three different types of oil, and a process has only recently been devised to create “virgin” carbon black—now termed sustainable carbon black—from the middle oil.

“So there is virgin carbon black from petrol; there is recovery of carbon black from pyrolysis; and now you have sustainable carbon black coming from the pyrolysis oil,” Roget summed. Even the lighter oil can be used to create resins used in the tires.

That’s important because the tire maker knows it will not be able to replace all of the needs for carbon black with only the recovered carbon black, Roget explained. The sustainable carbon black effectively closes the loop and ends the need for petroleum input for tires.

Carbon black via pyrolysis is already “very virtuous” energy-wise in an industrial operation, versus creating the original product, according to Roget, and it has the potential to be a lot cheaper. During pyrolysis, gas is captured, which can in turn be used to help heat the pyrolysis oven.

Michelin is hoping that more companies will help invest in a pyrolysis industrial base. It’s working with Bridgestone on this because as Roget says if they together present the specification they want for recovered carbon black, it will represent a big part of the industry.

Goodyear ElectricDrive GT tires for Tesla Model 3

Goodyear has also said it’s on board with recycled carbon black. It’s using Monolith’s carbon black from pyrolysis in a replacement tire for the Tesla Model 3.

Garcin described the collaboration with Bridgestone as “part of the bigger plan, as we have to really move towards 100% renewable and recycled materials in all of our tires.”

Sustainable tires require better recycling beyond reuse for tires

Around 90% of tires worldwide are recycled, while some markets within Africa still need to get onboard with the idea. Michelin and Bridgestone are currently organizing pilots on how to create a system for it in those markets.

“You have to obtain a material that has the same quality as the fossil material that you’re trying to replace. So that’s the first challenge,” said Roget.

For instance, PET (polyethylene terephthalate) is used as a reinforcement in passenger-car tires, and PET recovered directly from plastic bottles can replace that from fossil sources. The challenge for big potential users like Michelin is how you organize the collection of all the plastic bottles to buy as a consistent feedstock in the future.

It has to be cost-effective to recover and reuse materials, too. Synthetic rubber, or butadiene rubber, is “very cheap today,” said Roget, because it’s often made as a side product of gasoline production. Although the company is working on ways to produce it from agricultural waste, the cost is a barrier.

According to information from the U.S. Tire Manufacturers Association, synthetic polymers make up about 24% of the material in passenger vehicle and light truck tires.

Tire ingredients. – U.S. Tire Manufacturers Association

Emissions from tire wear

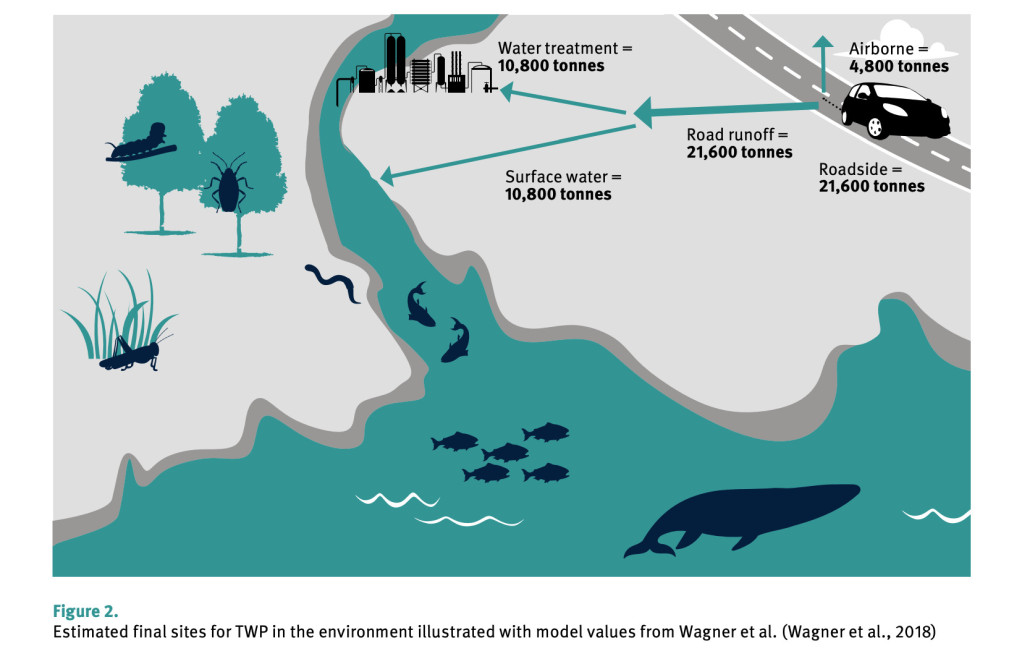

Finally, the elephant in the room is that tires emit their tread material as they wear, often in the form of particulate matter, some of which becomes airborne.

A 2023 study from Imperial College London suggested that, including what ends up in the ground and waterways, 52% of all global particle emissions from vehicles in 2021 came from tires and brakes, not exhaust, while globally 6.6 million tons of tire-wear particles are emitted annually. As the U.K. firm Emissions Analytics started pointing out in 2020, EV weight gains can result in colossally greater tire emissions.

How tire particulate emissions enter the environment (from Imperial College London 2023 report)

Michelin’s Roget is aware of this issue, and he says that a white paper on the matter is forthcoming. Michelin has improved on that metric by 11% from 2010 to 2020, he says. Continuing that progress while seeking better materials will in turn deliver more performance with less weight—both initially and lost to tread wear.

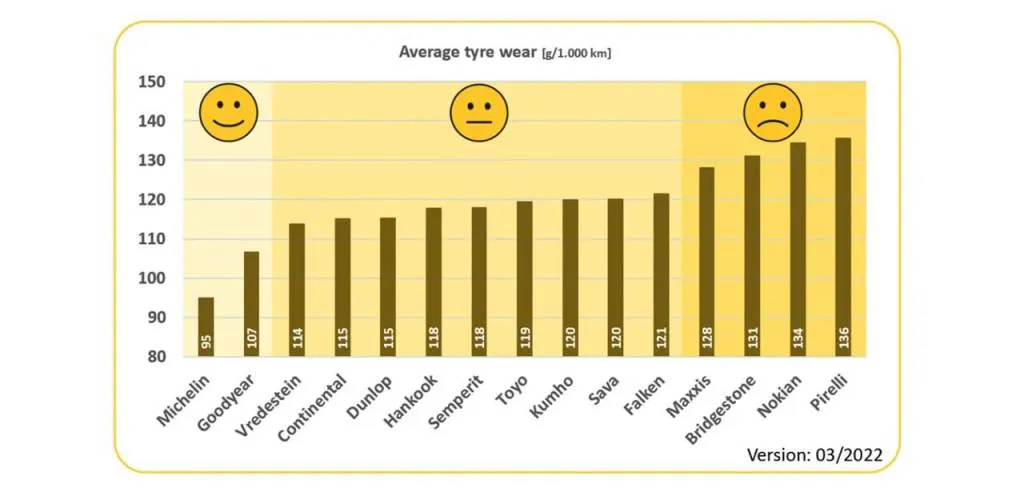

In a 2022 study from Europe’s largest automobile association, the ADAC, researchers found Michelin to be the lowest in the weight of tread compound lost per distance driven—the metric that directly corresponds with particulates left in the environment.

ADAC test of tire wear in weight per distance

All these examples underscore that sustainability isn’t open-ended. It’s a loop, and all of the points around that loop need to be well thought-out. With tires as the example, where the materials come from, where they end up, how they fail, the energy put into making them, and the energy savings they enable in use, are all considerations.

As the vehicles we drive transform to be part of a renewable loop, there’s no reason not to think the tires we roll on should transform too, even if that involves using fewer tires.

—

Michelin paid for meals and travel expenses relating to the demonstration of its tire technology and executive access.

Add a comment Cancel reply

Comments (0)

Related posts

Electric SUVs: Top 6 Models for Family Trips